A robot designed and built in Cornwall is being used for a new area of three dimensional surveying for the worldwide mining industry.

The RSV (Remote Surveying Vehicle) works twice as fast as a human and can be used where it is too dangerous for people to go.

James Jobling Purser, managing director of 3DMSI, and technical director Lucas Flumm, have just completed a contract surveying part of the deepest gold mine in the world.

Mponeng, owned by Anglo Gold Ashanti, is part of the old Western Deep levels Complex, near Johannesburg in South Africa. At its deepest point the mine travels 4.1km below surface. The mine employs 6,000 people with a further 10,000 being employed on the sister mines of Savuka and TauTona which are located nearby.

Jobling Purser designed and built the RSV while a studying at Camborne School of Mines at the University of Exeter’s Tremough campus – part of the Combined Universities in Cornwall (CUC). He has also had support from the CUC’s other Tremough-based partner, University College Falmouth and is based at its business incubation centre. Lucas also graduated – in Surveying – from the University of Exeter at Tremough.

He said: “We use the robot to speed up surveys of large mines as it can survey twice as quick as doing it manually. We only use it if there is dangerous areas to access or if we need to work quickly. The Mponeng survey was incredibly challenging because we had to walk about five kilometres underground with a lot of kit and temperatures of up to 40 degrees Centigrade.

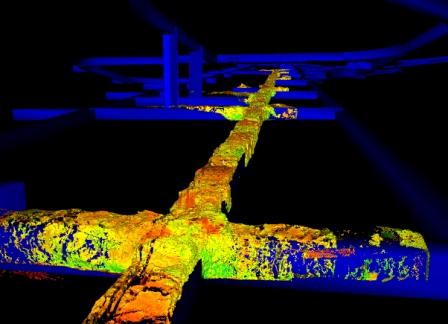

“We are using techniques that are more associated with the film industry and offering a global service applying them to mining problems. We are the first to use this for underground mining operations even though the oil and gas industry has been using similar technology for years. We can merge our 3D survey results with CAD designs of plant and engineering structures this allows us to identify problems that can easily be seen in 3D whereas previously the mining industry operated with two dimensional plans which are more difficult to use when interpolating 3D information.”

“We are aiming to use new technology to stay ahead of the game. This is made possible by the high speed Internet connections in Cornwall.”